A guide through the Hardware Engineering Tool Landscape 2019

In an era of “digitization”, “smart factories” and everything “4.0”, it is hard to keep an overview over the evolving engineering tool landscape for hardware development.

This blog post starts with a look at the three types of data that are crucial for hardware engineering. Then we compare key strengths and weaknesses of tools & methods that help managing that kind of data. A glossary for all abbreviations used in this article is attached at the end of the page.

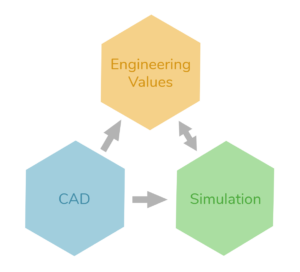

Hardware engineering = 3 types of data

In hardware development you will typically encounter three kinds of data:

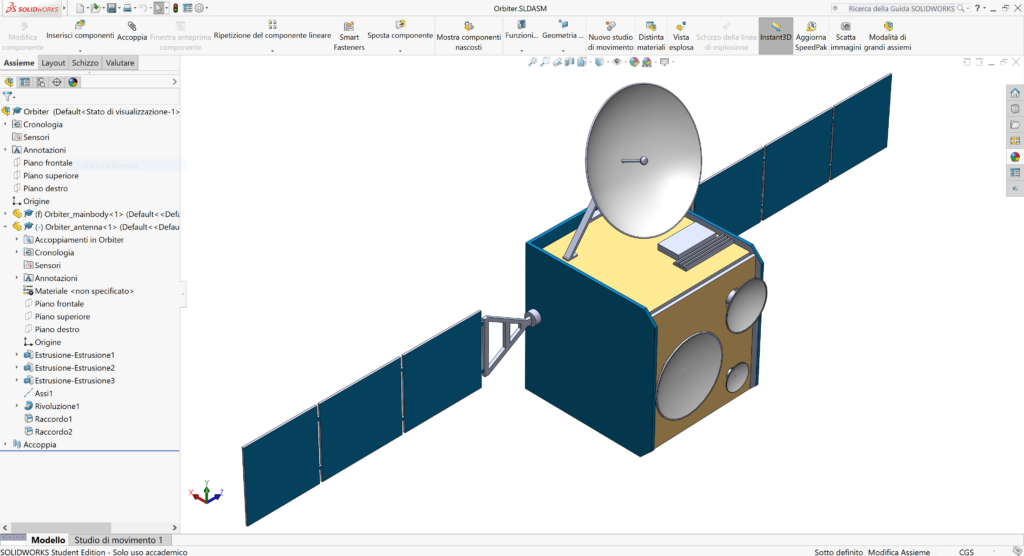

- CAD data

CAD data are the 3D models of your physical system.

This kind of data is usually created in CAD systems and then managed in PLM/PDM tools, to create BOMs (Bills of Materials), track as-designed vs. as-built configurations and connect to ERP systems for logistics tracking. While MCAD systems focus on mechanical design, ECAD Systems model electronic circuits.

- Simulation Data

Specialized models for detailed analysis of forces, fluids, dynamics, stresses, etc.

These simulations might be executed in specialized CAE/FEM/Thermal/Orbit/etc. simulation software, or can be custom written in MATLAB, Python or other languages.

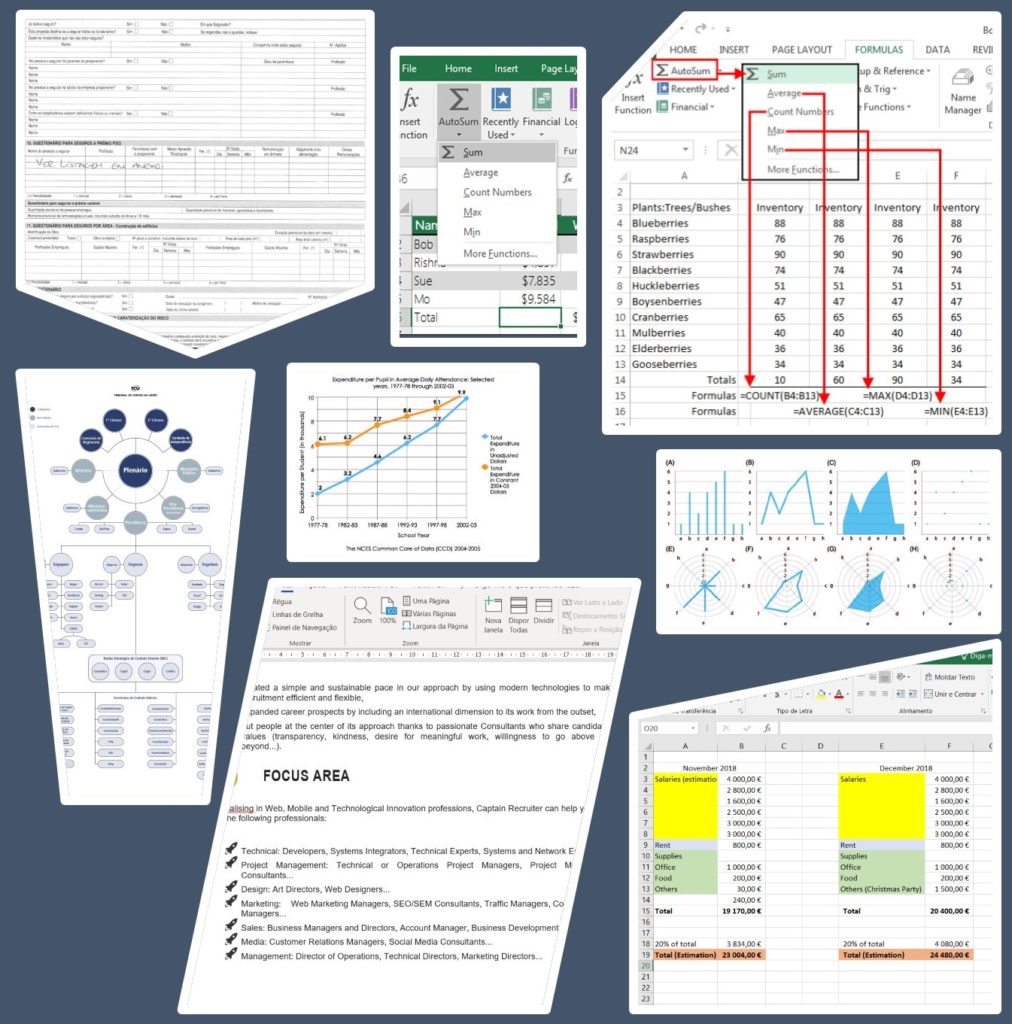

- All other non-CAD data (engineering values)

For example: power consumptions, data rates, velocities, temperatures, capacities, charging-cycles, operating modes, coefficients, efficiencies, etc.

These data are necessary for all kinds of analysis, trade-offs and simulations, but unfortunately usually not stored in a single place, but instead across hundreds of spreadsheets, reports, emails, wikis and many other files.

A huge part of engineering data today are buried in hundreds of inconsistent documents and Excel spreadsheets.

Mapping the tools to the data

In a classical approach these three types of engineering data are managed in the following tool families:

| Data | Produced in | Managed in |

|---|---|---|

| CAD | CAD software (Catia, Solidworks, etc.) |

PDM systems (Dassault SolidWorks, Autodesk Inventor, etc.) |

| Simulation | Simulation tools (Matlab, ANSYS, etc.) |

PLM systems (Siemens Teamcenter, PTC Windchill, etc.) |

| Engineering Values | Office tools (Word, Excel, etc.) |

Document Management Systems (DMS) / sometimes included in PLM (Microsoft Sharepoint, Siemens Teamcenter, etc.) |

This breakdown results in the following map of tool capabilities and strengths:

MBSE & DDSE

CAD and simulation tools have continuously been improved over the past decade and PDM/PLM tools have made it far easier to manage them even across big teams. However other tasks of systems engineers, such as the management of engineering values (connecting and comparing them as well as managing requirements and their impact on the system design) could not be solved by spreadsheets and document management systems. Instead, data had to be related and managed through new methods and tools; which led to the introduction of two complementary concepts:

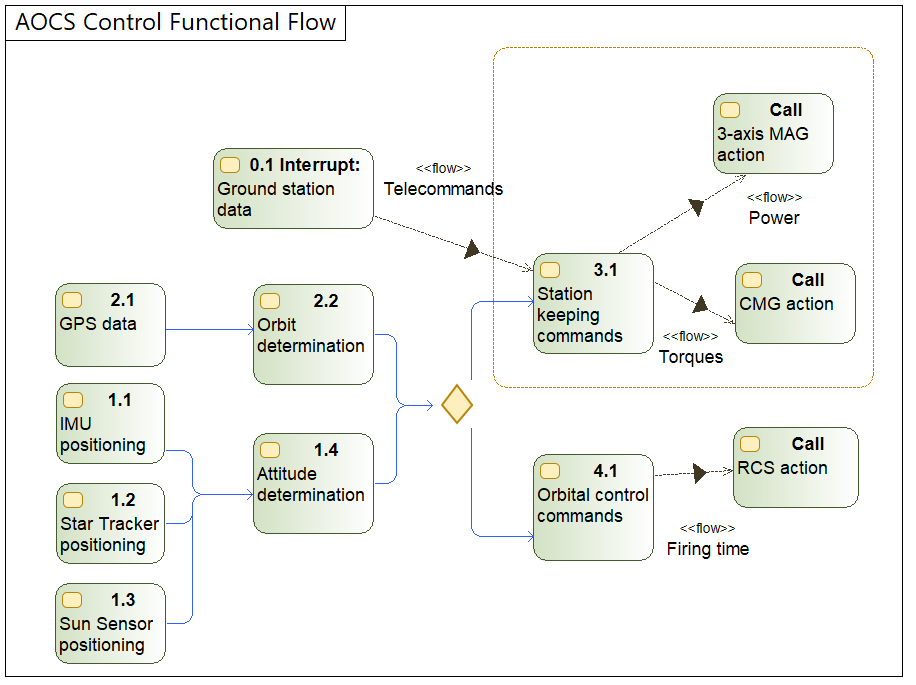

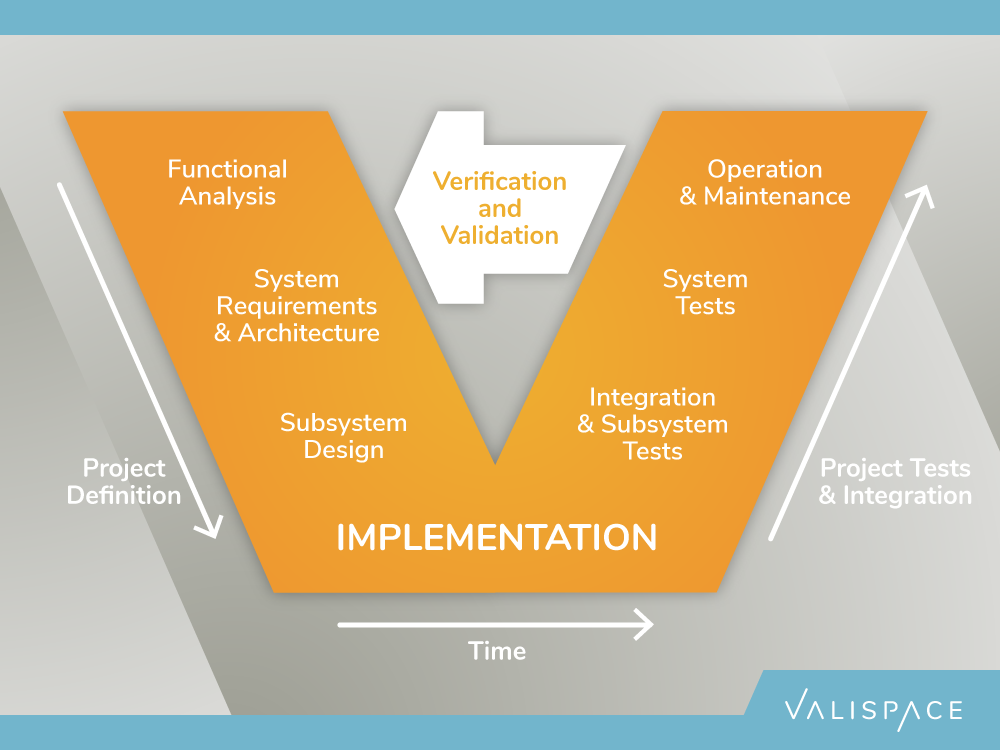

Model Based Systems Engineering (MBSE)

In MBSE, engineers start by modelling the functions of the product that they are developing. These functions are then converted and traced into requirements and system diagrams, that describe the functionality of the product.

MBSE has been used in complex product development, such as for space systems and is gaining popularity in more and more industries, mainly in the Form of SysML.

MBSE tools are usually expert tools, used at the early stages of product development by a small group of engineers. The resulting documents and graphs are the backbone for a large part of the engineering effort of complex products and provide an overview over the system architecture.

Data Driven Systems Engineering (DDSE)

The models of MBSE cover the functional design overview and requirements. After their development and their breakdown into detailed design, the actual implementation begins. This implementation phase can take years for complex products, in which countless data are produced.

In the implementation phase, DDSE tools:

- Manage non-CAD data & engineering values

- Integrate different software-tools through one single data hub

(“Single Source of Truth”) - Automatically propagate changes through documents and simulations

(“Technical Change Management”) - Are collaborative tools that allow for simultaneous multi-user access

Documents that are created from DDSE data, are stored in PLM/PDM systems, to record the as-built-status.

DDSE tools are used and accessible by all engineers in the project: providing systems engineers with the necessary technological overview and experts with the up-to-date values and design baseline.

DDSE tools manage engineering data in the implementation phase, provide version control, make it available collaboratively and provide full traceability to the entire engineering team.

The overall overview is therefore given in the completed tool strength map:

DDSE and MBSE complement each other and the classical hardware engineering toolstack. Any modern hardware company should be digitized in 2019 and have their data connected, stored and versioned in the appropriate tools.

Valispace is the leading browser-based DDSE tool, used by the world’s most innovative hardware companies, such as Airbus, GOMspace, OHB LuxSpace, DLR and Tekever.

Valispace is a single source of truth and collaboration platform for all your engineering data. Click here to get a demo and try it for free.

Thank you for reading.

Would you like to contribute to the blog?

Send us your idea to contact-us@valispace.com

Or

Abbreviations

BOM – Bill of Materials

CAD – Computer Aided Design

CAE – Computer Aided Engineering

DDSE – Data Driven Systems Engineering

DMS – Document management System

ECAD – Electronic Computer Aided Design

ERP – Enterprise Resource Planning

FEM – Finite Element Method

MBSE – Model Based Systems Engineering

MCAD – Mechanical Computer Aided Design

PDM – Product Data Management

PLM – Product Lifecycle Management

SysML – Systems Modeling Language